Expander 999

Remote Control with Autopilot Function

The Auto Pilot is designed to allow the machine to work independently of the operator and run automatically, drastically reducing your labour costs.

With this amazing system, Klindex machines can grind on their own the entire area moving forward, turning and coming back, crossing the grinding tracks leaving no untreated parts. Without any interruption, it is also possible to modify all the variables of the machine with a comfortable, handy and intuitive remote control. The auto pilot kit is an optional available only on request.

Productivity per hour

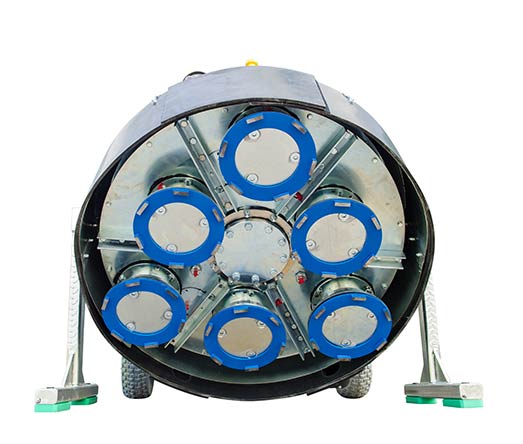

Expander 999

The ultimate in large surface floor finishing, polishing and grinding, the Expander 999 is set apart by its 6 staggered counter-rotating heads for perfect surface levelling. With the 6 staggered heads the flatness of the surface and the perfect balance of the floor grinding machine is guaranteed.

Features

- Innovative automated tool change system: the head rotates 90° allowing the operator to change the tools without having to lift the grinding machine.

- Adjustable work pressure from 500Kg to 1350 Kg

- Extremely strong metal gear system within the Planetario head without a belt driven system that is subject to breaking.

- Radio Remote control: multidirectional joystick to avoid vibrations to the operator and offers a completely automated operation.

- Low noise levels in order to work on any site

- Extractable front wheel for easy transportation and accessibility

- Revolutionary Dust Extraction system with effective collection of all types of residue: from thin powders to heavy concrete dust

- No vibrations to the operator

- Quick Attack diamond holding system allows quick and easy diamond tool changing without the need for hammers or tools.

Technical Data

- Motor

Volts

Hertz

Amps

Speed Tools

Working Width

Pressure Work

Tool Size

Water Tank

Dimensions

Weight - 25HP

380-480V

50/60Hz

35A

300-1300rpm

999mm

500-1350Kg

6x240mm

46L

170x150x105mm

1347Kg

Key Features and Capabilities

Remote Control with Autopilot

Significantly reduce stress to the operator while increasing productivity – the perfect combination. The Autopilot is the next step in the evolution of floor grinding. The Autopilot is designed to allow the machine to work independently of the operator and run automatically, drastically reducing your labor costs.

Rigid Head

The machine design does not focus weight and pressure upon the chassis to make the head ‘float’ over the floor but rather directly on the planetary heads. This ensures that the floor is not ‘wavy’ and that the machine is rigid over the top of the grinding area to ensure the flattest floor possible.

Effective weight distribution

The motor is placed situated directly over the top of the planetary head alongside the water tank with three well balanced grinding heads for perfect distribution of weight, allowing the highest grinding pressure available. The design permits the machine to work effectively on all surfaces, including concrete as well as all types of stone such as marble and granite.

Large working width

With a working section of 999mm and 6 heads the Expander 999 is amongst the biggest floor grinding machinery in the world.

Adjustable working head pressure

New technology which allows for better and easier grinding. The pressure is adjusted according to an electronic actuator.

Steel geared Planetary head

Planetary head is 100% tempered steel. With metal gears driving an active planetary system means that the main disc and satellites always run, allowing the machine to work hard with high performance.

meet the family

expander range

Download the expander brochure Here

Checkout the complete range of Expander series floor grinding machines and explore the best picks for your floor

Expander in action

Watch how our machines grind and polish different floors

Concrete floors

Granite floors

Marble floors

The Klindex range of grinding machines are specially designed to suit all types of flooring or benches, making them one the most versatile machinery ranges available on the market today with full metal gearing the machines are designed with a clear focus on the needs of the customer.